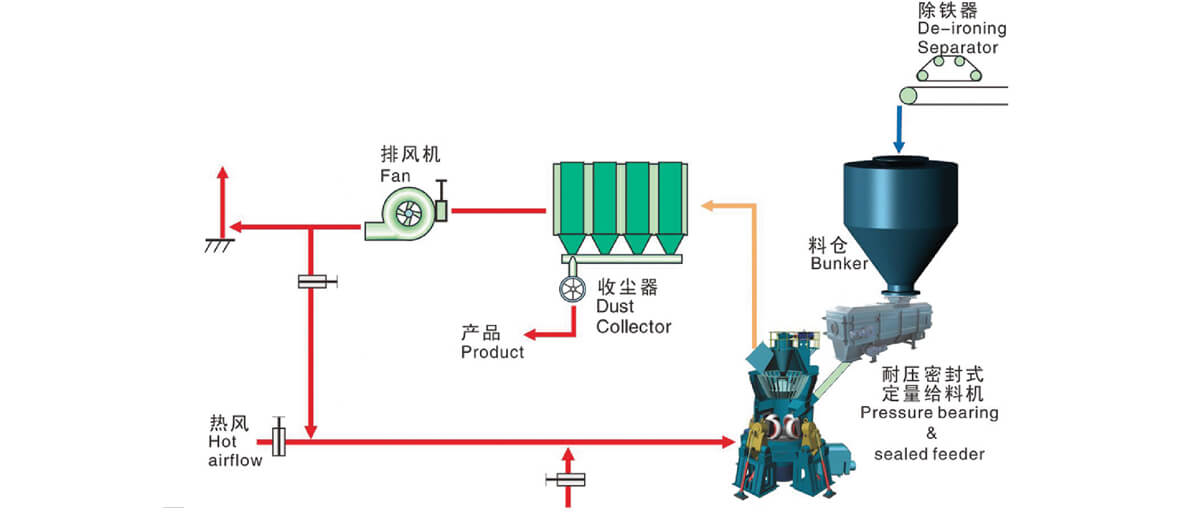

Sehlahisoa sa ho qetela se na le boleng bo tsitsitseng. Nako e kgutshwane ya ho dula ha thepa e lokelang ho silwa e ka netefatsa sebopeho se lekanang sa dikarolwana le mokelikeli o motle. Dikahare tse mmalwa tsa tshepe di bonolo ho di tlosa ho netefatsa bosweu bo phahameng le bohlweki.

utloisisa

NA U HLOKA THAROLLO?Bakeng sa tlhahisoleseling e batsi ka feme ea ho sila kapa kopo ea khotheishene, ka kopo ikopanye le rona.

Dipatlisisoiteanye le rona

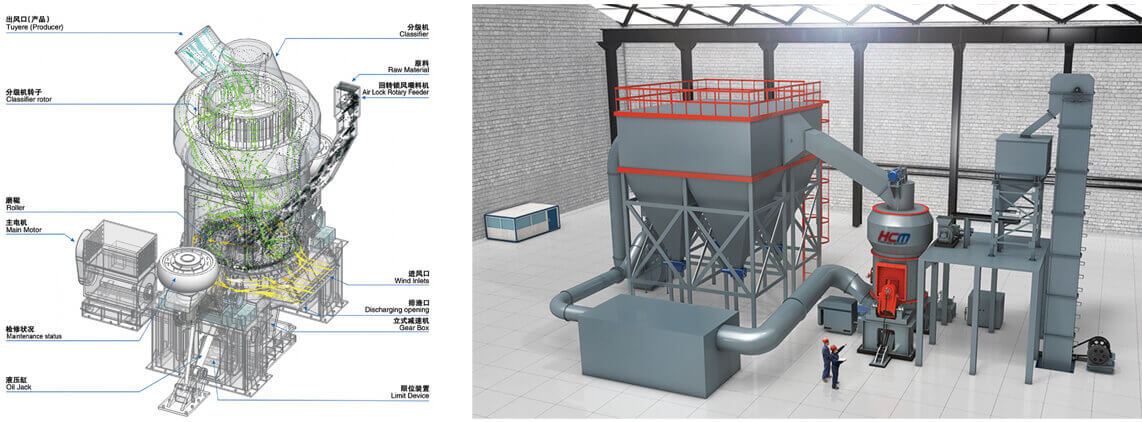

Rea u amohela ho Guilin HongchengGuilin HongCheng Mining Equipment Manufacture Co., Ltd.

- Mohala:86-15107733434

- Aterese:Yangtang Shanshui Industrial Park, Xicheng Economic Development Zone, Guilin City, Profinseng ea Guangxi, China

- Imeile:hcmkt@hcmilling.com

- Mohala:+91 97125 28918

- Imeile:hgvala@gmail.com

Motsamaisi oa papatso oa India

© Tokelo ea Mongoli - 2010-2025: Litokelo Tsohle li Sirelelitsoe.Lihlahisoa tse Chesang - 'Mapa oa sebaka

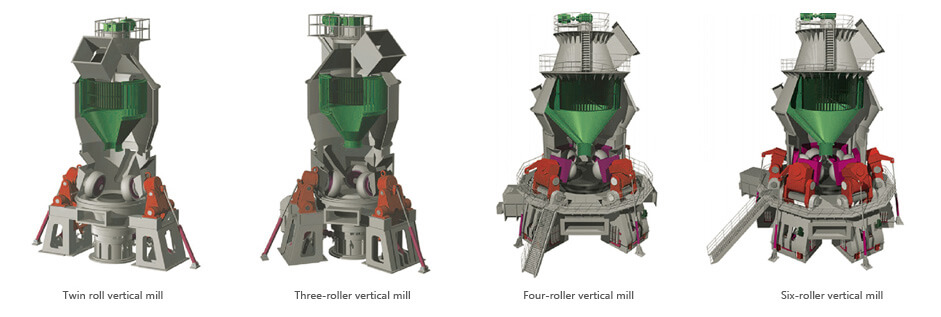

Ho Sila ha Mashala, Semela se Setle sa ho Sila sa Ultra Fine, Selikali se Setle sa Ultra, Mochini oa ho Roller oa Petroleum Coke o Tebileng, Sesebelisoa sa ho Sila, Selei sa ho Sila sa Pente ea Phofo se Tsoang Chaena,

Ho Sila ha Mashala, Semela se Setle sa ho Sila sa Ultra Fine, Selikali se Setle sa Ultra, Mochini oa ho Roller oa Petroleum Coke o Tebileng, Sesebelisoa sa ho Sila, Selei sa ho Sila sa Pente ea Phofo se Tsoang Chaena,