Sebopeho le Molao-motheo

Litheko tse potlakileng le tse ntle, baeletsi ba nang le tsebo ho u thusa ho khetha sehlahisoa se nepahetseng se lumellanang le likhetho tsohle tsa hau, nako e khuts'oane ea tlhahiso, taolo ea boleng bo holimo e ikarabellang le lits'ebeletso tse fapaneng bakeng sa litaba tsa ho lefa le ho romella thepa bakeng sa Mochini oa ho Sila oa 'Mabole o Hloahloa, Boleng bo holimo e tla ba ntlha ea bohlokoa bakeng sa mokhatlo oo ho ikhetholla ho bahlolisani ba bang. Na ua bona hore na ua lumela, u batla tlhaiso-leseling e batsi? Leka feela lihlahisoa tsa oona!

Litheko tse potlakileng le tse ntle, baeletsi ba nang le tsebo ho u thusa ho khetha sehlahisoa se nepahetseng se lumellanang le likhetho tsohle tsa hau, nako e khuts'oane ea tlhahiso, taolo ea boleng bo holimo e ikarabellang le lits'ebeletso tse fapaneng tsa ho lefa le ho romella thepa bakeng saSelei sa ho Sila sa Phofo sa Mabole sa Chaena, Selei sa ho Sila sa Lejoe la Kalaka, Liodara tse ikhethileng lia amoheleha ka boleng bo fapaneng le moralo o ikhethang oa bareki. Re ntse re labalabela ho theha tšebelisano-'moho e ntle le e atlehileng khoebong le lipehelong tse telele ho tsoa ho bareki ba lefats'e ka bophara.

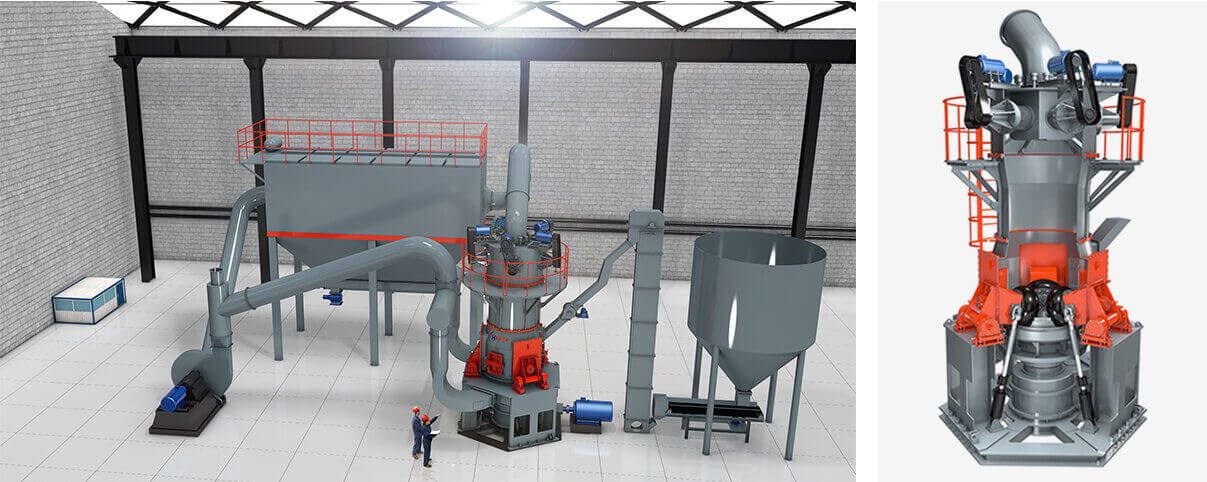

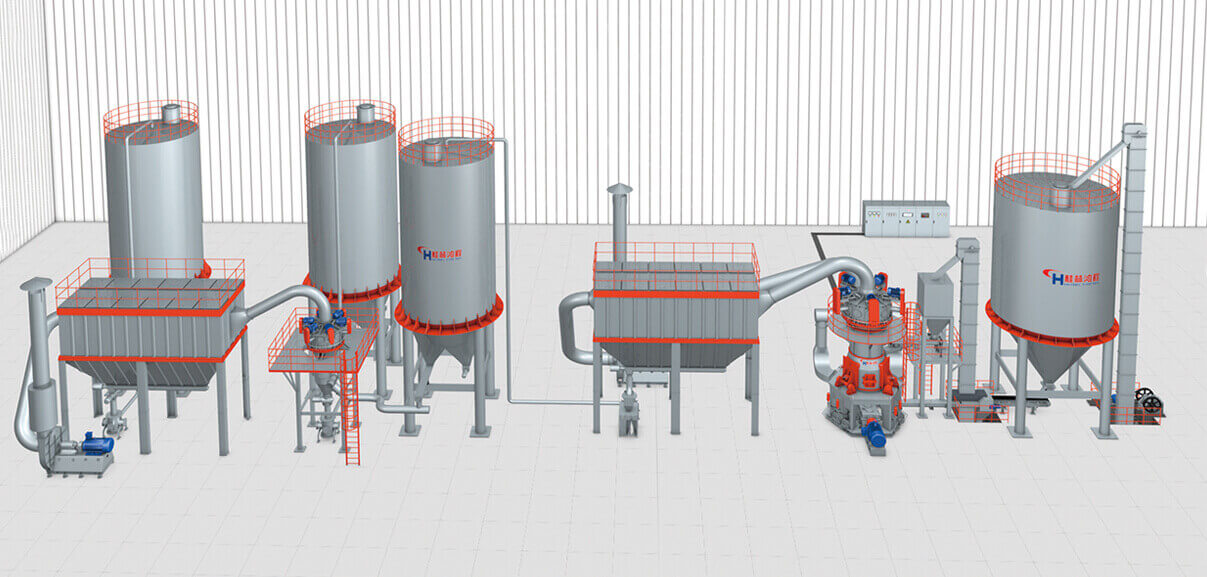

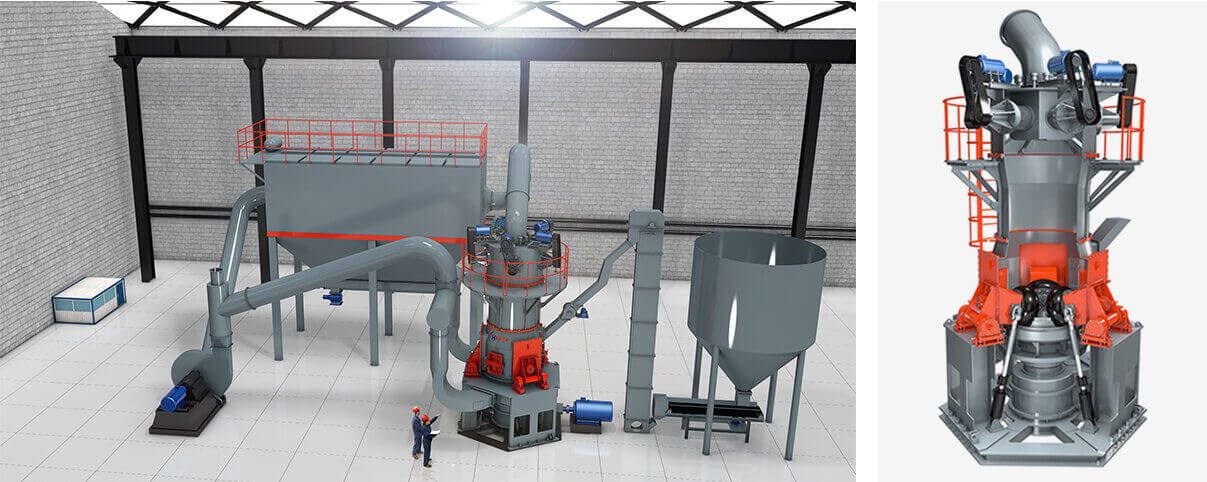

Enjene e kganna sesebediswa se fokotsang mocheso ho potoloha daele, thepa e tala e iswa bohareng ba daele ho tloha ho feeder e potolohang ya moya. Thepa e tsamaya ho ya pheletsong ya daele ka lebaka la tshusumetso ya matla a centrifugal mme e silwe ke matla a rolara mme e pshatlwe tlasa extrusion, sila le ho seha. Ka nako e le nngwe, moya o chesang o foka ho potoloha daele mme o nyolle thepa ya fatshe. Moya o chesang o tla omisa thepa e phaphametseng mme o fokele thepa e mahoashe ho daele. Phofo e ntle e tla tliswa ho classifier, mme ebe, phofo e ntle e tshwanelehang e tla phalla ka hara lelwala mme e bokellwe ke moqokeledi wa lerōle, ha phofo e mahoashe e tla wela fatshe daeleng ka lehare la classifier mme e silwe hape. Potoloho ena ke tshebetso yohle ya ho sila.

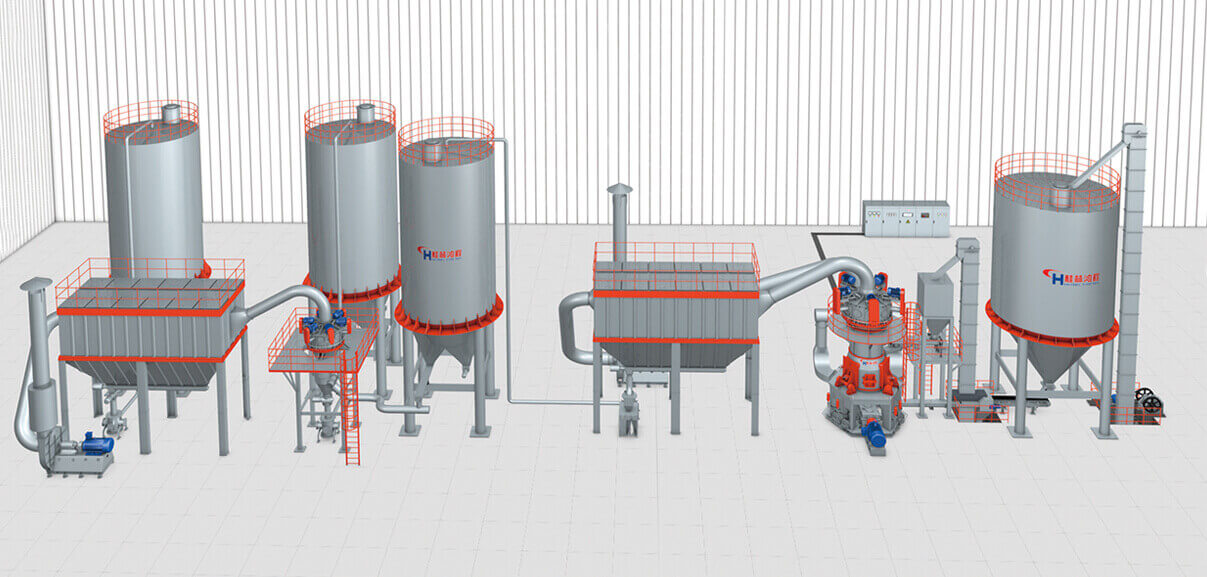

Sistimi ea Bobeli ea ho Hlopha

Sistimi ea bobeli ea ho arola e kenyelletsa sesebelisoa sa ho arola se setle haholo, fene, pokello ea lerōle, sehokelo, sesebelisoa sa ho tsamaisa likurufu le liphaephe. Sesebelisoa sa ho arola ke mochini oa mantlha oa sistimi eohle. Sethala sa HLMX se setle haholo se nang le sistimi ea sesebelisoa sa ho arola se seng ka katleho, se khonang ho arola phofo e mahoashe ho phofo e ntle ho fumana lihlahisoa tse fapaneng tse boreleli pakeng tsa letlooeng la 800 ho isa ho la 2000.

Likarolo tsa sistimi ea bobeli ea ho arola

Bokgoni bo phahameng ba ho arola: Sehlophisi le fene di laolwa ke taolo ya lebelo la phetoho ya maqhubu. Ka ho fetola lebelo la sehlophisi le impeller ya fene, botenya bo fapaneng ba sehlahiswa sa ho qetela se tsitsitseng le se tshepahalang bo ka fumanwa ka potlako. Bokgoni ba ho arola bo hodimo.

Sehlopha: Sesebelisoa sa ho arola phofo se sebetsang hantle haholo le se bolokang matla. Rotor e le 'ngoe kapa rotor e mengata e sebelisoa ho hlahisa boholo ba likaroloana tse ka fetoloang ka lebaka la tlhoko ea 'nete.

Mefuta e mengata ea botenya: Sistimi ea ho arola e khona ho khetha likaroloana tse tšesaane ho tsoa thepa. Botenya bo ka tloha ho letlooeng la 800 ho isa ho letlooeng la 2000. Ka sistimi ea bobeli ea ho arola e ka fumana boholo bo fapaneng ba likaroloana, 'me e ka boela ea fumana boholo bo tšoanang ba likaroloana ka bongata bo phahameng.

Litheko tse potlakileng le tse ntle, baeletsi ba nang le tsebo ho u thusa ho khetha sehlahisoa se nepahetseng se lumellanang le likhetho tsohle tsa hau, nako e khuts'oane ea tlhahiso, taolo ea boleng bo holimo e ikarabellang le lits'ebeletso tse fapaneng bakeng sa litaba tsa ho lefa le ho romella bakeng sa Tlhahlobo ea Boleng bakeng sa Mochini oa Mochini oa Mochini oa ho Sila o Hloahloa oa China, Boleng bo holimo e tla ba ntlha ea bohlokoa bakeng sa mokhatlo oo ho ikhetholla ho bahlolisani ba bang. Na ua bona hore na ua lumela, u batla tlhaiso-leseling e batsi? Leka feela lihlahisoa tsa eona!

Litheko tse potlakileng le tse ntle, baeletsi ba nang le tsebo ho u thusa ho khetha sehlahisoa se nepahetseng se lumellanang le likhetho tsohle tsa hau, nako e khuts'oane ea tlhahiso, taolo ea boleng bo holimo e ikarabellang le lits'ebeletso tse fapaneng bakeng sa litaba tsa ho lefa le ho romella bakeng sa Tlhahlobo ea Boleng bakeng sa Mochini oa Mochini oa Mochini oa ho Sila o Hloahloa oa China, Boleng bo holimo e tla ba ntlha ea bohlokoa bakeng sa mokhatlo oo ho ikhetholla ho bahlolisani ba bang. Na ua bona hore na ua lumela, u batla tlhaiso-leseling e batsi? Leka feela lihlahisoa tsa eona!

Tlhahlobo ea Boleng bakeng sa Mochini oa ho Sila oa Phofo ea Micro Powder oa China,Selei sa ho Sila sa Lejoe la Kalaka, Liodara tse ikhethileng lia amoheleha ka boleng bo fapaneng le moralo o ikhethang oa bareki. Re ntse re labalabela ho theha tšebelisano-'moho e ntle le e atlehileng khoebong le lipehelong tse telele ho tsoa ho bareki ba lefats'e ka bophara.

Re ka rata ho u khothaletsa mohlala o motle oa mochini oa ho sila ho netefatsa hore u fumana liphetho tse lakatsehang tsa ho sila. Ka kopo re bolelle lipotso tse latelang:

1.Thepa ea hau e tala?

2. Ho hlokahala botenya (letlooeng/μm)?

3. Bokgoni bo hlokahalang (t/h)?

Litheko tse potlakileng le tse ntle, baeletsi ba nang le tsebo ho u thusa ho khetha sehlahisoa se nepahetseng se lumellanang le likhetho tsohle tsa hau, nako e khuts'oane ea tlhahiso, taolo ea boleng bo holimo e ikarabellang le lits'ebeletso tse fapaneng bakeng sa litaba tsa ho lefa le ho romella bakeng sa Tlhahlobo ea Boleng bakeng sa Mochini oa Mochini oa Mochini oa ho Sila o Hloahloa oa China, Boleng bo holimo e tla ba ntlha ea bohlokoa bakeng sa mokhatlo oo ho ikhetholla ho bahlolisani ba bang. Na ua bona hore na ua lumela, u batla tlhaiso-leseling e batsi? Leka feela lihlahisoa tsa eona!

Litheko tse potlakileng le tse ntle, baeletsi ba nang le tsebo ho u thusa ho khetha sehlahisoa se nepahetseng se lumellanang le likhetho tsohle tsa hau, nako e khuts'oane ea tlhahiso, taolo ea boleng bo holimo e ikarabellang le lits'ebeletso tse fapaneng bakeng sa litaba tsa ho lefa le ho romella bakeng sa Tlhahlobo ea Boleng bakeng sa Mochini oa Mochini oa Mochini oa ho Sila o Hloahloa oa China, Boleng bo holimo e tla ba ntlha ea bohlokoa bakeng sa mokhatlo oo ho ikhetholla ho bahlolisani ba bang. Na ua bona hore na ua lumela, u batla tlhaiso-leseling e batsi? Leka feela lihlahisoa tsa eona!