Khalase ea litšila ke mofuta oa litšila tsa malapeng, boteng ba eona ha bo bake feela kotsi le tšitiso tlhahisong le bophelong ba batho, empa hape bo tlisa tšilafalo tikolohong, bo lula mobung oa bohlokoa, 'me bo eketsa moroalo oa tikoloho. Ho hakanngoa hore Chaena e hlahisa lithane tse ka bang limilione tse 3.2 tsa khalase ea litšila selemo se seng le se seng, e leng hoo e ka bang 2% ea kakaretso ea litšila tse tiileng tsa masepala. Ka ntlafatso ea matla a felletseng a naha le ntlafatso ea maemo a bophelo a batho, kakaretso ea khalase ea litšila le eona e eketsehile. Mabapi le ho sebelisa khalase ea litšila hape, linaha tse ling tse tsoetseng pele United Kingdom le United States li fihletse liphetho tse makatsang. Linaha tsa Europe le Amerika li sebelisitse khalase ea litšila ka katleho mererong ea kaho, e leng tsela e sebetsang ea ho sebelisa khalase e ngata ea litšila. Hobane mefuta eohle ea khalase ea litšila ha e hloke ho hlophisoa, ha ho hlokahale hore ho be le 'mala. Mohlala, khalase ea litšila e sebetsoa e le thepa ea mokhabiso oa moaho ho Mosaic. Joaloka moetsi oa mochini oa khalase ea litšila, mochini oa khalase oa litšila o hlahisoang ke HCM Machinery o fana ka thuso e ntle ea lisebelisoa bakeng sa ho sebelisa khalase ea litšila hape. Kajeno, re tla hlahisa ts'ebetso ea tlhahiso ea khalase ea litšila ea Mosaic.

1. Ho rua molemo lefikeng la phosphate: Ho rua molemo lefikeng la phosphate ke mohato wa pele tshebetsong ya lefika la phosphate, e leng se ikemiseditseng ho arola diminerale tse nang le thuso ho ditshila tse lefikeng la phosphate ka mekgwa ya mmele le ya dikhemikhale. Mekhoa e tlwaelehileng ya ho rua molemo e kenyeletsa karohano ya matla a kgoheli, ho phaphamala le karohano ya makenete. Karohano ya matla a kgoheli e sebedisa phapang ya bongata ba diminerale tse lejweng bakeng sa karohano, ho phaphamala ho sebedisa phapang ya ho phaphamala ha diminerale tse lejweng bakeng sa karohano, mme karohano ya makenete e sebedisa phapang ya makenete ya diminerale tse lejweng bakeng sa karohano.

2. Ho sila le ho sila lefika la phosphate: lefika la phosphate kamora ho nona, le hloka ho silwa le ho phekoloa ka ho sila, e le ho lokolla diminerale tse thusang ka hara lejwe la minerale hamolemo. Ho sila hangata ho sebediswa sesenyi sa jaw, sesenyi sa cone le disebediswa tse ding ho roba lejwe la phosphate hore e be boholo bo loketseng ba dikarolwana. Ho sila ke tshebediso ya mochini o moholo wa tlhahiso le ho sebetsana le phofo ya phosphate ho sila lejwe le silakaneng hantle, e le hore le fihlelle ditlhoko tse hlokahalang tsa botenya.

3. Ho dutla ha lefika la phosphate: Ho dutla ha lefika ke mohato wa bohlokwa tshebetsong ya lefika la phosphate, leo ka lona metsoako e thusang jwalo ka phosphate e ka qhibilihiswang ho tswa lejweng. Mekhoa e sebediswang haholo ya ho dutla e kenyeletsa ho dutla ha asiti, ho dutla ha alkali le ho dutla ha oxidation. Ho dutla ha asiti ho sebedisa tharollo ya asiti ho qhibilihisa phosphate, ho dutla ha alkaline ho sebedisa tharollo ya alkaline ho qhibilihisa phosphate, mme ho dutla ha oxidative ho sebedisa moemeli wa oxidizing ho qhibilihisa phosphate.

4. Pula le ho sefa majwe a phosphate: Kamora ho ntsha metsi, tharollo ya dikarolo tse thusang tse kang phosphate e hloka ho sefa le ho sefa ho arola dihlahiswa tsa phosphate e tiileng. Pula ke tshebediso ya sesebediswa se nosetsang metsi ho fetola karolo ya phosphate ya tharollo hore e be pula e tiileng, mme ho sefa ke karohano ya seretse ho tswa ho tharollo ka disebediswa tsa ho sefa.

5. Ho omisa le ho sila lefika la phosphate: Kamora hore seretse se sefshoe, se hloka ho omiswa le ho silafatswa ho fumana sehlahiswa sa phosphate se fedileng. Ho omisa ke tshebediso ya disebediswa tsa ho omisa ho fetola metsi a seretse hore a fetohe mouoane, mme ho silafatswa ke ho omisa seretse ka mocheso o phahameng, e le hore se thehe dikarolwana tse teteaneng tsa phosphate.

6. Kalafo ea mesaletsa ea phosphate ore: Ts'ebetso ea ho sebetsana le phosphate ore e tla hlahisa palo e itseng ea mesaletsa, mesaletsa e na le liminerale le litšila tse sa ntšoang. E le ho fokotsa tšilafalo ea tikoloho le tšenyo ea mehloli, mesaletsa e hloka ho phekoloa. Mekhoa e tloaelehileng ea kalafo ea mesaletsa e kenyelletsa ho bokella mesaletsa, ho sebelisa hape mesaletsa le tšebeliso e felletseng ea mesaletsa.

Mokhoa oa tlhahiso ea khalase ea ho sebelisa hape lithōle tsa khalase ea Mosaic: mokhoa oa ho sila le mokhoa oa ho qhibilihisa li sebelisoa ka kakaretso, 'me mokhoa oa tlhahiso oa mokhoa oa ho sila le Mosaic oa ceramic li tšoana hantle. Mokhoa o ka sehloohong oa tlhahiso ke ho sila khalase ea lithōle ka har'a leloala la khalase ea lithōle ho fihlela litlhoko tsa botenya ba phofo ea khalase, ebe u eketsa tekanyo e itseng ea moemeli ea khomarelang (kankere e sa tloaelehang kapa ea organic) le moemeli oa ho taka kapa moemeli oa ho tlosa 'mala, ka motsoako ho e kopanya hore e be motsoako o tšoanang. Motsoako o hatelloa ka libopeho tse fapaneng tsa jeometri ka mokhoa oa ho hatella o omileng, 'me' mele o omisitsoeng o romeloa ho ontong ea roller, ontong ea poleiti ea push le ontong ea tunnel ka mocheso oa likhato tse 800-900 tsa Celsius bakeng sa ho sila. Ka kakaretso, o lula sebakeng sa mocheso oa ho sila ka lihora tse 1.5-2.5. Ha lihlahisoa li ntse li pholile ka ontong bakeng sa tlhahlobo, ho beoa, ho omisoa, ho hlahlojoa, ho paka, polokelo kapa fektheri, lihlahisoa tse sa tšoanelehang li sebelisoa hape. Mokhoa oa ho qhibilihisa o thehiloe holim'a khalase ea litšila (palo ea batho ke 25-60%) e le thepa e tala ea mantlha, ho eketsoa bongata bo itseng ba lehlabathe la silica, feldspar, limestone, soda ash le emulsion agent, e leng setlolo sa ho daea ka mokhoa oa ho sila khalase ea litšila hore e be phofo e tšoanang, ebe e kenngoa ka ontong ea ho qhibiliha ea mocheso o phahameng (mocheso oa ho qhibiliha ke 1400-1500) ho qhibiliha hore e be mokelikeli oa khalase o tšoanang. Mokelikeli oa khalase o phalla ka har'a khalendara 'me o hatelloa ka har'a boloko ba khalase ea boholo le sebopeho se itseng, e romelloang ontong ea ho qhibilihisa. Lihlahisoa tse qhibilihisitsoeng li ka bolokoa kapa tsa tlisoa kamora tlhahlobo, ho beoa le ho paka.

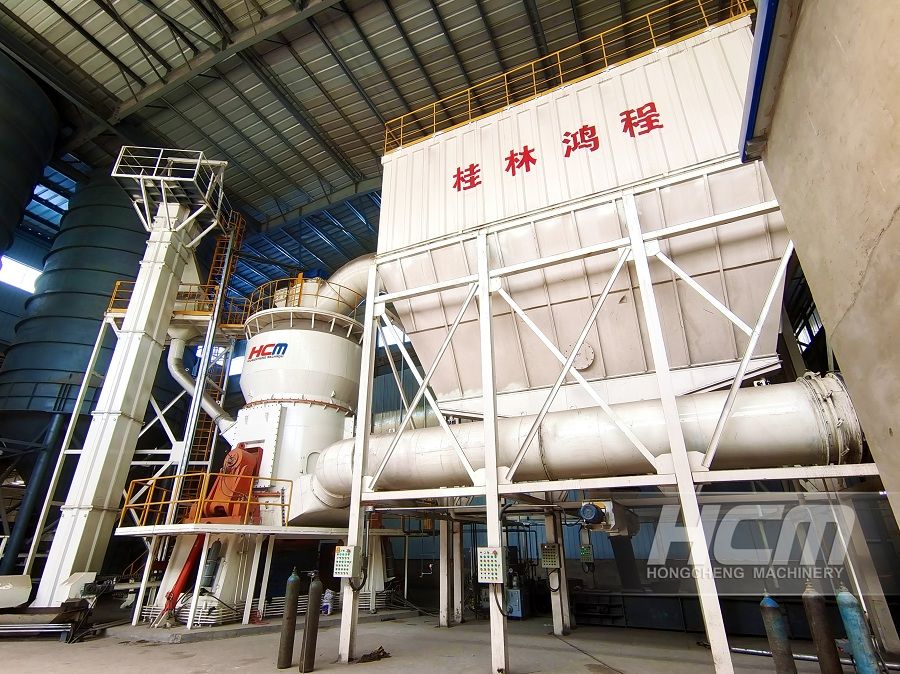

Ho sebelisa hape li-mosaic tsa khalase ho thehiloe ho sileng khalase ea lithōle hore e be phofo ea khalase. Mochini oa khalase ea lithōle ke sesebelisoa sa tlhahiso bakeng sa ho sebetsana le phofo ea khalase. Mochini oa khalase ea lithōle o hlahisoang keMechine ea HCM has HC, HCQ and other models, which can process 80-400 mesh glass powder with large output, low energy consumption, small equipment area and simple technology. If you have waste glass recycling needs, welcome to call us to learn more about waste glass mill equipment:hcmkt@hcmilling.com

Nako ea poso: Pherekhong-08-2024