Selelekela ho Mashala

Mashala ke mofuta oa diminerale tsa mesaletsa ea khale tse nang le khabone. A hlophisitsoe ka khabone, haedrojene, oksijene, naetrojene le likarolo tse ling, tseo boholo ba tsona li sebelisoang e le mafura ke batho. Hona joale, mashala a na le makhetlo a 63 a palo e bolokiloeng e batlisisitsoeng ho feta peterole. Mashala a ne a bitsoa khauta e ntšo 'me lijo tsa indasteri, ke matla a maholo ho tloha lekholong la bo18 la lilemo. Nakong ea Phetohelo ea Liindasteri, hammoho le ho qaptjoa le ho sebelisoa ha enjene ea mouoane, mashala a sebelisoa haholo e le mafura a indasteri 'me a tlisitse matla a maholo a tlhahiso a e-s'o ka a e-ba teng sechabeng.

Tšebeliso ea Mashala

Mashala a Chaena a arotsoe ka mekhahlelo e leshome. Ka kakaretso, mashala a se nang mafura, mashala a coking, mashala a mafura, mashala a khase, mashala a sa kopanngoeng hantle, a sa tlamang le mashala a malelele kaofela a bitsoa mashala a bituminous; Mashala a se nang mafura a bitsoa semi Anthracite; Haeba tekanyo ea ho feto-fetoha ha mocheso e feta 40%, e bitsoa lignite.

Tafole ea lihlopha tsa mashala (haholo-holo mashala a phehang)

| Sehlopha | Mashala a bonolo | Mashala a manyane | Mashala a se nang mafura | Mashala a ho pheha | Mashala a mafura | Mashala a khase | Mashala a fokolang a tlamo | Mashala a sa tlameng | Mashala a malelele a mollo | Mashala a sootho |

| Ho feto-fetoha ha maemo | 0~10 | >10~20 | >14~20 | 14~30 | 26~37 | >30 | >20~37 | >20~37 | >37 | >40 |

| Litšobotsi tsa Cinder | / | 0 (phofo) | 0 (liboloko) 8~20 | 12-25 | 12-25 | 9~25 | 0(liboloko)~9 | 0 (phofo) | 0~5 | / |

Lefifi:

Bongata ba yona e kgolo, e sootho bo lefifi, e benya haholo, e hlephile; E na le dintho tse feto-fetohang tse ka bang 40%, ntlha e tlase ya ho hotetsa mme e bonolo ho tshwara mollo. Hangata e sebediswa ho etsa khase, indastering ya ho qhibilihisa metsi, boiler ya motlakase, jj.

Mashala a bituminous:

Ka kakaretso e na le dikotwana, e nyane ebile e le phofo, boholo ba yona e ntšo ebile e benya, e na le sebopeho se setle, e na le matter e feto-fetohang e fetang 30%, ntlha e tlase ya ho hotetsa mme e bonolo ho hotetsa; Mashala a mangata a bituminous aa khomarela mme a bonolo ho a lahla nakong ya ho hotetsa. A sebediswa indastering ya ho pheha, ho kopanya mashala, ho boiler ya motlakase le indasteri ya ho etsa khase.

Anthracite:

Ho na le mefuta e 'meli ea phofo le likotoana tse nyane, tse ntšo, tse tšepe le tse benyang. Litšila tse fokolang, sebopeho se kopaneng, khabone e tsitsitseng e phahameng, ho fihlela ho feta 80%; Likahare tse feto-fetohang li tlase, ka tlase ho 10%, ntlha ea ho hotetsa e phahame, 'me ha ho bonolo ho tšoara mollo. Ho tla eketsoa mashala le mobu o loketseng bakeng sa ho chesa ho fokotsa matla a mollo. E ka sebelisoa ho etsa khase kapa ka kotloloho e le mafura.

Phallo ea ts'ebetso ea ho sila mashala

Bakeng sa ho sila mashala, e itshetlehile haholo hodima coefficient ya yona ya ho sila ha Harzburg. Ha coefficient ya ho sila ha Harzburg e le kgolo, ho sila ho ba betere (≥ 65), mme coefficient ya ho sila ha Harzburg e le nyane, ho sila ho ba thata (55-60).

Litlhaloso:

2 Khetha mochini o ka sehloohong ho latela litlhoko tsa tlhahiso le botenya;

② Kopo e ka sehloohong: mashala a phutliloeng a chesang

Tlhahlobo ea mehlala ea tšilo ea ho sila

1. Semela sa pendulum (HC, semela sa mashala se silafaditsweng sa letoto la HCQ):

Litšenyehelo tse tlase tsa matsete, tlhahiso e phahameng, tšebeliso e tlase ea matla, lisebelisoa tse tsitsitseng le lerata le tlase; Bothata ke hore litšenyehelo tsa ts'ebetso le tlhokomelo li phahame ho feta tsa tšilo e otlolohileng.

Tafole ea bokhoni ba leloala la ho sila la letoto la HC (200 mesh D90)

|

| HC1300 | HC1700 | HC2000 |

| Bokgoni (t/h) | 3-5 | 8-12 | 15-20 |

| Enjene e kholo ea sileila (kw) | 90 | 160 | 315 |

| Enjene ea ho letsa (kw) | 90 | 160 | 315 |

| Enjene ea Classifier (kw) | 15 | 22 | 75 |

Litlhaloso (phetoho e kholo):

① Sistimi ea potoloho e bulehileng e nang le patente ea Hongcheng e sebelisoa bakeng sa mashala a lignite le malakabe a malelele a nang le ho feto-fetoha ho hoholo.

② Foreimi ea lipalesa tsa plum e nang le sebopeho sa pendulum e otlolohileng e sebelisa sebopeho sa matsoho, se nang le phello e betere.

③ Sesebelisoa se thibelang ho phatloha se etselitsoe sistimi.

④ Moqokeleli oa lerōle le phaephe li lokela ho etsoa ho qoba ho bokellana ha lerōle ka hohle kamoo ho ka khonehang.

⑤ Bakeng sa sistimi ea ho tsamaisa phofo, ho khothaletsoa hore bareki ba sebelise mokhoa oa ho tsamaisa khase le ho eketsa sistimi ea ho tsamaisa naetrojene le ea ho lemoha nitric oxide ka maemo a itseng.

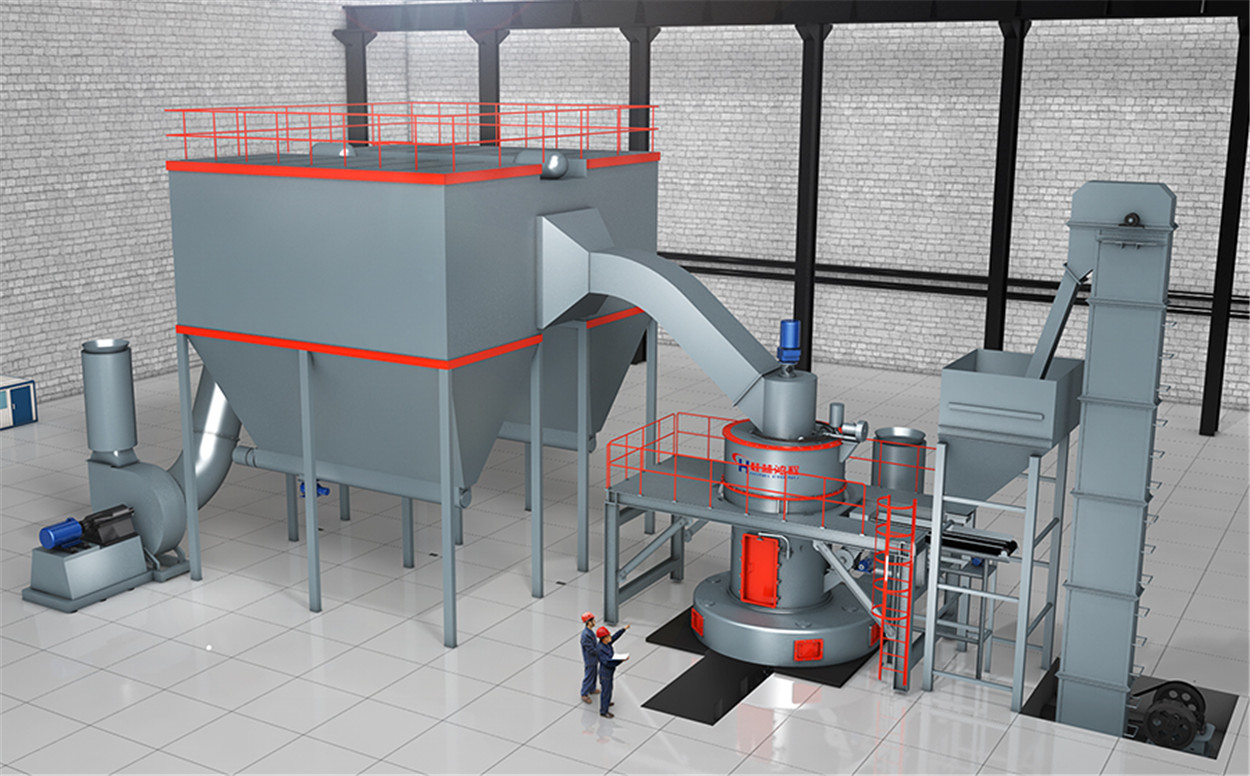

2. Selei sa mashala se otlolohileng (selei sa mashala se otlolohileng sa HLM):

Tlhahiso e phahameng, tlhahiso e kgolo, sekgahla se tlase sa tlhokomelo, tekanyo e phahameng ya boiketsetso le theknoloji ya moya o chesang o hodileng. Bothata ke ditjeo tse phahameng tsa matsete le sebaka se seholo sa mokatong.

Litlhaloso le liparamente tsa tekheniki tsa leloala la mashala le silang la HLM (indasteri ea tšepe)

| Mohlala | HLM1300MF | HLM1500MF | HLM1700MF | HLM1900MF | HLM2200MF | HLM2400MF | HLM2800MF |

| Bokgoni (t/h) | 13-17 | 18-22 | 22-30 | 30-40 | 40-50 | 50-70 | 70-100 |

| Mongobo oa thepa | ≤15% | ||||||

| Botle ba sehlahisoa | D80 | ||||||

| Mongobo oa sehlahisoa | ≤1% | ||||||

| Matla a motlakase a maholo (kw) | 160 | 250 | 315 | 400 | 500 | 630 | 800 |

Mokhahlelo oa I:Cho potlaka ha thepa e tala

E kholoMashalaThepa e silwa ke sehatsetsi ho fihlela e le botenya ba phepelo (15mm-50mm) e ka kenang leloaleng la ho sila.

SethalengII: Gho phunya

E sithabetsengMashalaLisebelisoa tse nyane li romeloa holong ea polokelo ka lifti, ebe li romeloa kamoreng ea ho sila ea leloala ka ho lekana le ka bongata ke sesebelisoa sa ho fepa bakeng sa ho sila.

Mokhahlelo oa Boraro:Hlopha ka sehlophaho ing

Lisebelisoa tse sitsoeng li lekanngoa ke sistimi ea ho lekanya, 'me phofo e sa tšoaneleheng e lekanngoa ke sesebelisoa sa ho arola 'me e khutlisetsoa mochining o moholo bakeng sa ho sila hape.

SethalengV: Cho bokella lihlahisoa tse felileng

Phofo e lumellanang le botenya e phalla ka phaepheng le khase mme e kena ka hara moqokeledi wa lerole bakeng sa karohano le pokello. Phofo e bokelletsweng e fedisitsweng e romelwa silo ya sehlahiswa se fedisitsweng ke sesebediswa sa ho tsamaisa ka kou ya ho ntsha, ebe e pakwa ke tanka ya phofo kapa moqokeledi wa othomathiki.

Mehlala ea ts'ebeliso ea ts'ebetso ea phofo ea mashala

Mohlala le palo ea lisebelisoa tsena: Lisete tse 3 tsa li-mill tsa ho sila tsa sistimi ea potoloho e bulehileng ea HC1700

Ho sebetsana le thepa e tala: Anthracite

Botebo ba sehlahisoa se felileng: 200 letlooeng D92

Bokgoni ba Lisebelisoa: lithane tse 8-12 / hora

Morero ona ke ho fana ka mashala a sitsitsoeng bakeng sa boiler e chesitsoeng ka mashala ea sistimi ea ho futhumatsa ka tlas'a lefatše morafong oa mashala oa Bulianta oa sehlopha. Rakonteraka ea akaretsang oa projeke ena ke China Academy of Coal Sciences. Ho tloha ka 2009, Chinese Academy of Coal Sciences e bile molekane oa maano oa Hongcheng le selekane se matla. Merero eohle ea boiler e chesitsoeng ka mashala le ea mashala a sitsitsoeng e sebelisa mochini oa ho sila oa Hongcheng bakeng sa ho bapisa sistimi. Lilemong tse 6 tse fetileng, Hongcheng e sebelisane ka tieo le Academy of Coal Sciences, 'me merero ea ho sila mashala a sitsitsoeng e hasane libakeng tsohle tse kholo tsa tlhahiso ea mashala Chaena. Morero ona o amohela lihlopha tse tharo tsa li-mill tsa Raymond tse nang le sistimi ea potoloho e bulehileng ea HC1700, tse etselitsoeng ka ho khetheha ho sila mashala a sitsitsoeng. Hc1700 e sitsitsoeng mashala e sebelisa potoloho e bulehileng, ho kenya sesebelisoa se thibelang ho phatloha le mehato e meng, 'me sistimi e bolokehile ebile e ka tšeptjoa. Tlhahiso ea mochini oa HC1700 e phahame ka 30-40% ho feta mochini oa setso oa ho sila oa pendulum, o bolokang matla le o mosa tikolohong.

Nako ea poso: Mphalane-22-2021